- Jump to:

WHO WE ARE

We are Tilsatec, specialists in high-performance hand, arm, and body protection – now trailblazers in high-impact hand protection

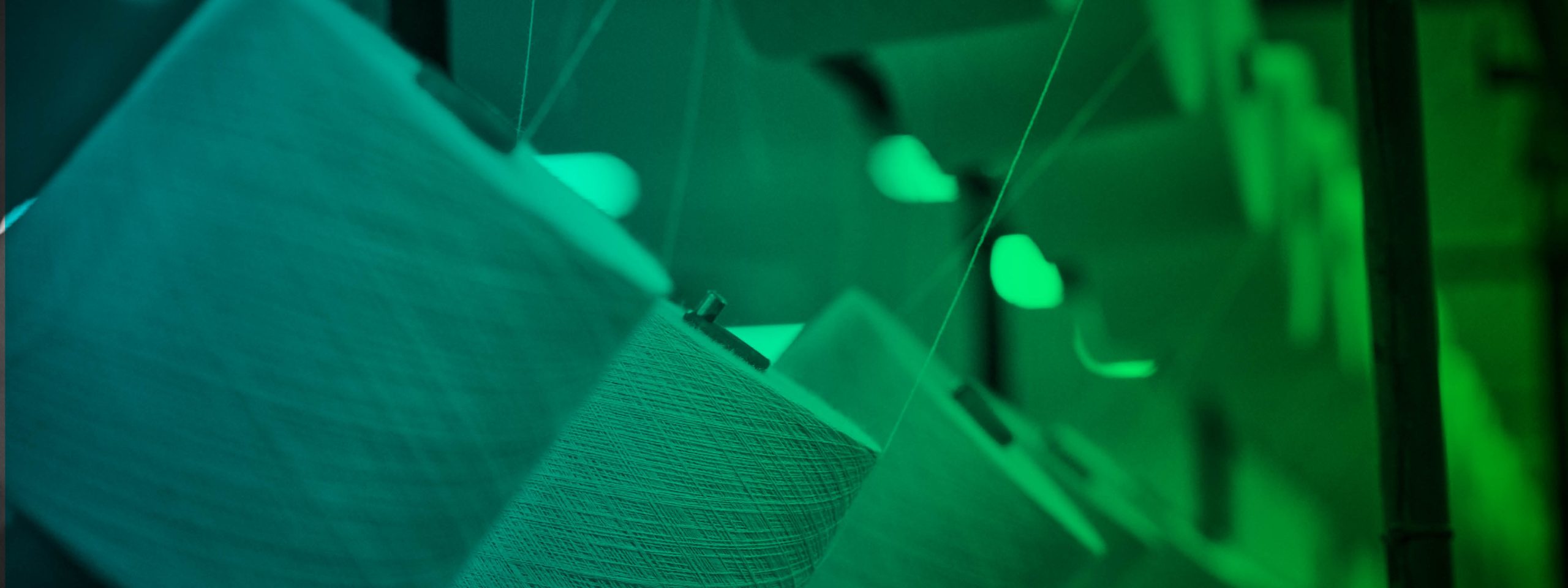

Originating in Wakefield, England with offices across the UK, Canada, and the United States, Tilsatec has been a leading global manufacturer of advanced, high–performance materials for hand and arm protection for over 20 years. With a legacy of developing technical yarns and materials that goes back over two decades, we’re still innovating with Collide-x – next level impact protection for the world’s hardest-working hands.

The RhinoYarn mark is your sign of quality and means that product has been made with our proprietary cut-resistant yarn technology. RhinoYarn technology is an engineered yarn process that combines various technical fibers and materials. Such materials can be used on their own, but when blended together to create a composite yarn, they can achieve significantly higher levels of cut protection, without compromising on comfort or dexterity.

At Tilsatec, we never stand still in the quest to bring our customers the best possible PPE. Creating our own purpose-built independent research and development laboratory means we’re always testing new ideas and fresh combinations of materials while maintaining stringent due diligence and quality control.

Built to international ISO 17025 standards and accredited by UKAS, our laboratory is equipped to conduct mechanical testing of abrasion, tear, puncture, and cut resistance to European EN 388 and EN 420 standards and ANSI/ISEA 105-2016 standards, as well as ANSI/ISEA 138-2019 and EN 388 standards for impact protection.

Three Collide-x gloves are also tested for resistance to contact heat according to European standard EN 407: 2020.

Understanding impact protection standards

Wherever people work in high hazard environments, wherever there are cut and puncture hazards, sharps or needles, our products are at the front line, helping them do their jobs safely and efficiently.

With operations around the UK, United States, and Canada, our team works in close partnership with customers to design and develop PPE solutions from the ground up.