What Is a Nitrile Coating?

A nitrile coating is a synthetic rubber compound, specifically a copolymer of acrylonitrile and butadiene. The material is man-made and is applied to a gloves’ liner through a dipping process, the resulting coating offers a protective layer with many key benefits including;

- Durability and Abrasion Resistance: Nitrile is inherently tough, and resists wear and tear, extending the life of the glove

- Oil and Chemical Resistance: It offers good resistance to many oils, fuels, and liquids, making it suitable for various industrial applications

- Excellent Grip: The textured surface of many nitrile coatings enhances grip, improving handling and safety

- Puncture Resistance: While not puncture-proof, nitrile offers a degree of resistance to punctures and snags

- Latex-Free: This is a significant advantage for individuals with latex allergies

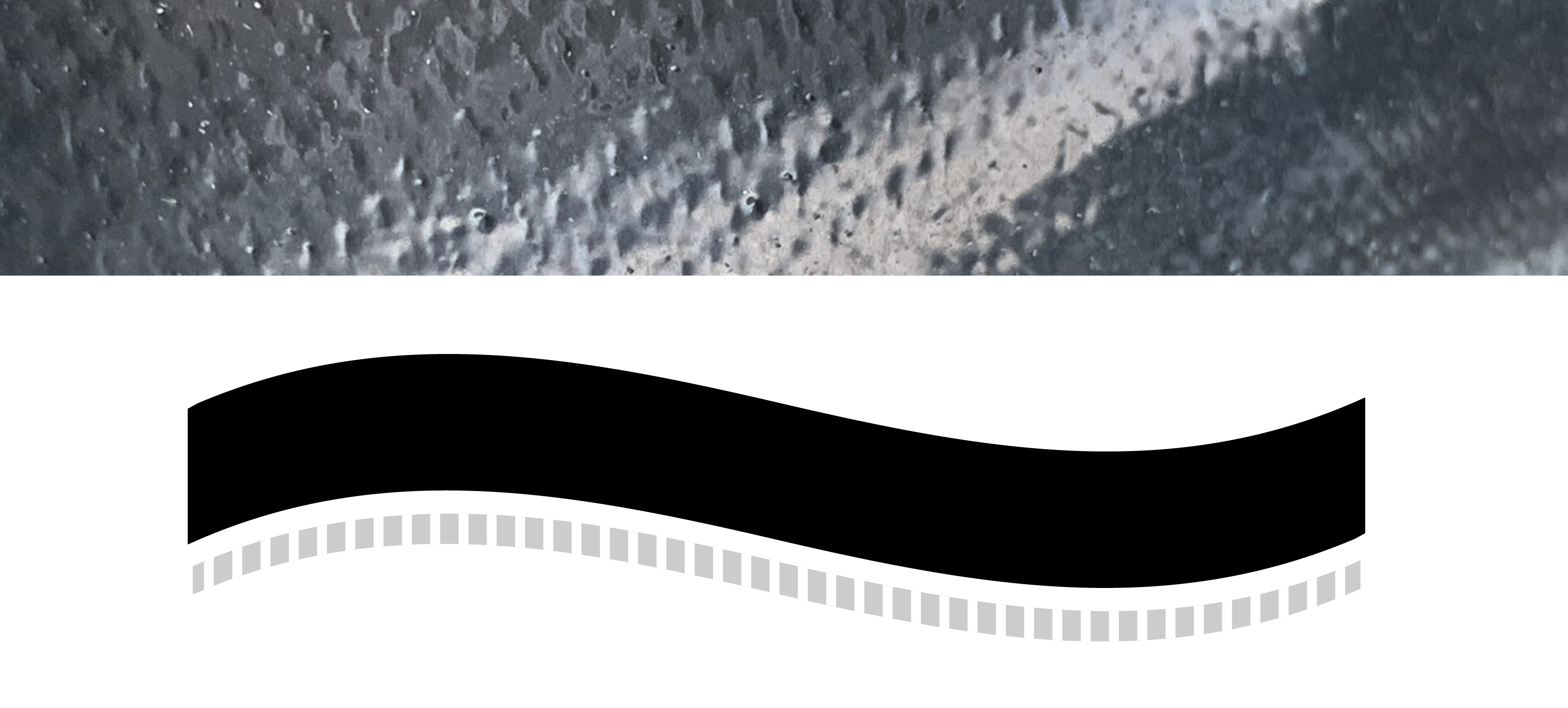

Flat Nitrile

A flat nitrile palm coating creates a smooth, continuous layer over the palm and often the fingers. For example. Key features of flat nitrile include:

- High Durability: The solid nitrile layer provides excellent resistance to abrasion and punctures

- Reliable Dry Grip: It offers a secure grip in dry handling conditions

- Waterproof Protection: The nitrile coating provides a barrier against liquids, keeping hands dry

- Good Dexterity: While durable, flat nitrile coatings can still allow for reasonable dexterity, depending on the thickness

- Typical Applications: General handling, packaging, construction, maintenance, and tasks requiring water resistance

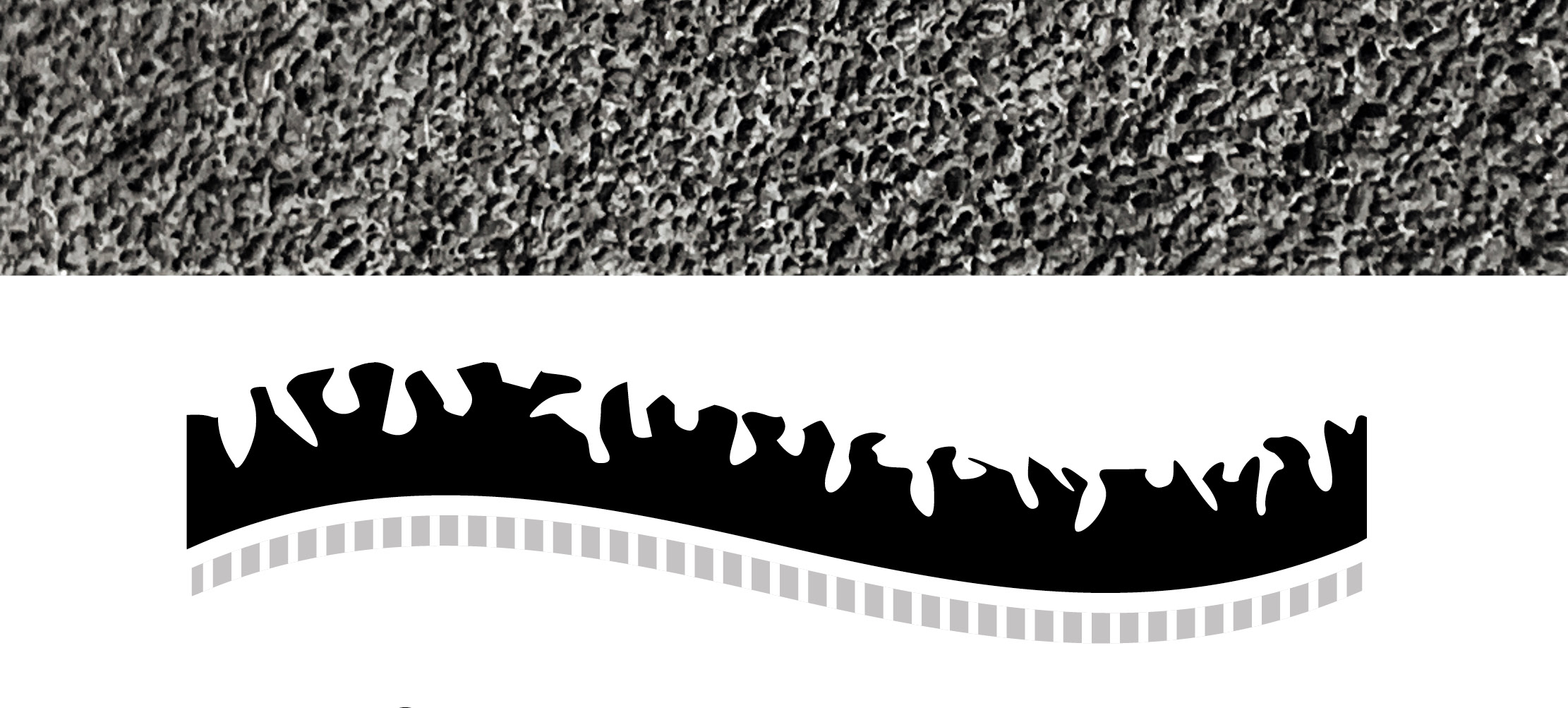

Sandy Foam Nitrile

A sandy foam nitrile coating has a textured, slightly porous surface that feels somewhat like fine sandpaper. The sandy foam nitrile coating, as seen in our 55-6121 Lightweight cut level F glove with a sandy foam palm, offers a unique structure that provides:

- Superior Grip in Oily and Wet Conditions: The micro-channels and increased surface area effectively displace liquids, maintaining excellent contact with the handled object

- Good Abrasion Resistance: The nitrile base still provides a good level of durability

- Enhanced Dexterity and Breathability Compared to Flat Nitrile: The foamed structure can offer more flexibility and allow for some airflow, improving comfort during extended use

- Typical Applications: Automotive, engineering, oil and gas, metal fabrication, and any task involving handling oily or wet components

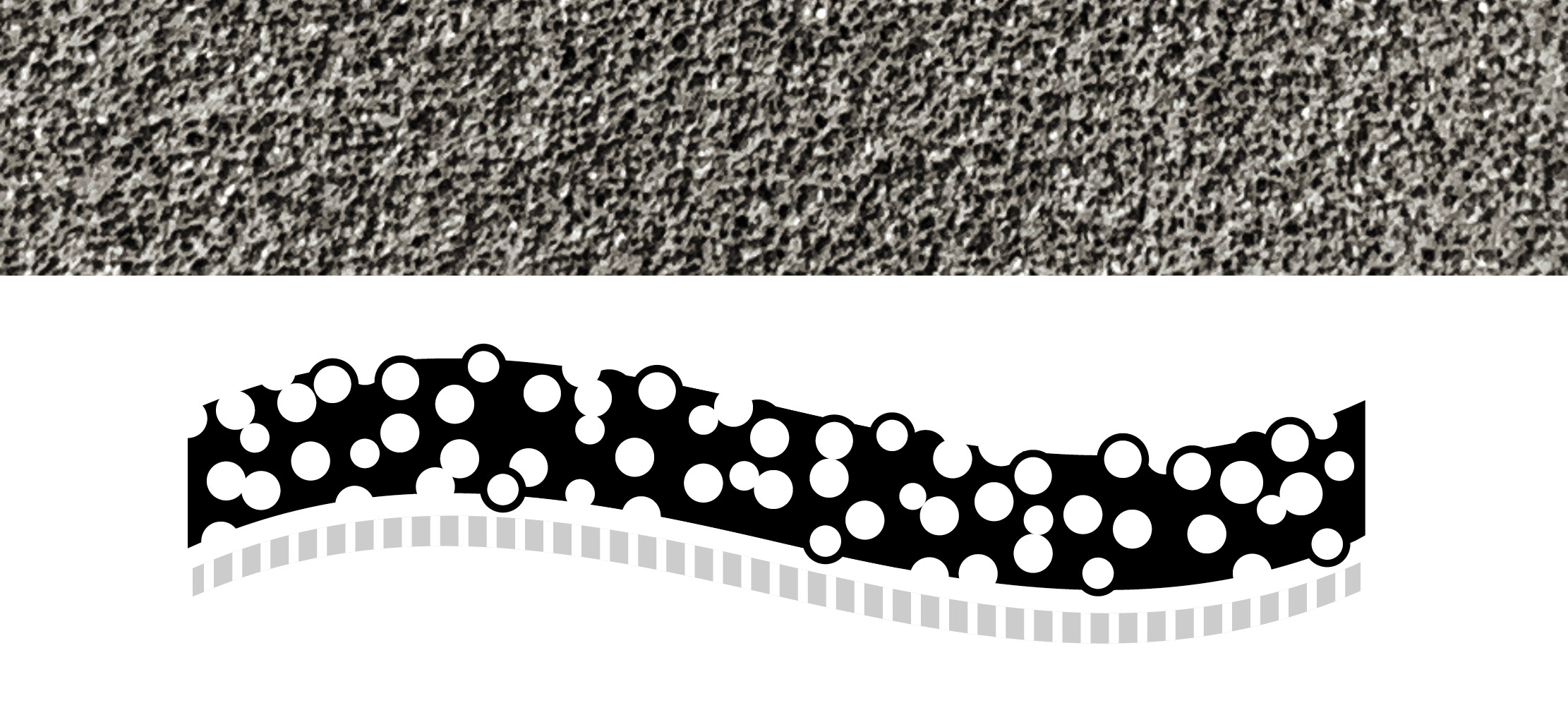

Microfoam Nitrile

This is a specific type of foamed nitrile that creates a very fine, almost cellular structure. It’s known for its exceptional breathability, flexibility, and excellent grip in both wet and dry conditions. Gloves such as the 55-6125 Lightweight cut level F glove are often very comfortable for extended wear. This unique construction delivers a distinct set of advantages:

- Exceptional Breathability: The open-cell structure allows for excellent air circulation, keeping hands cooler and drier during prolonged use, which significantly enhances comfort

- Superior Flexibility and Dexterity: The thin and pliable nature of microfoam nitrile allows for a high degree of tactile sensitivity and ease of movement, making it ideal for intricate handling tasks

- Excellent Grip in Wet and Dry Conditions: The fine, porous surface provides reliable grip on various materials, even in slightly damp or oily environments

- Lightweight Feel: Gloves with microfoam nitrile coatings are often lightweight, reducing hand fatigue

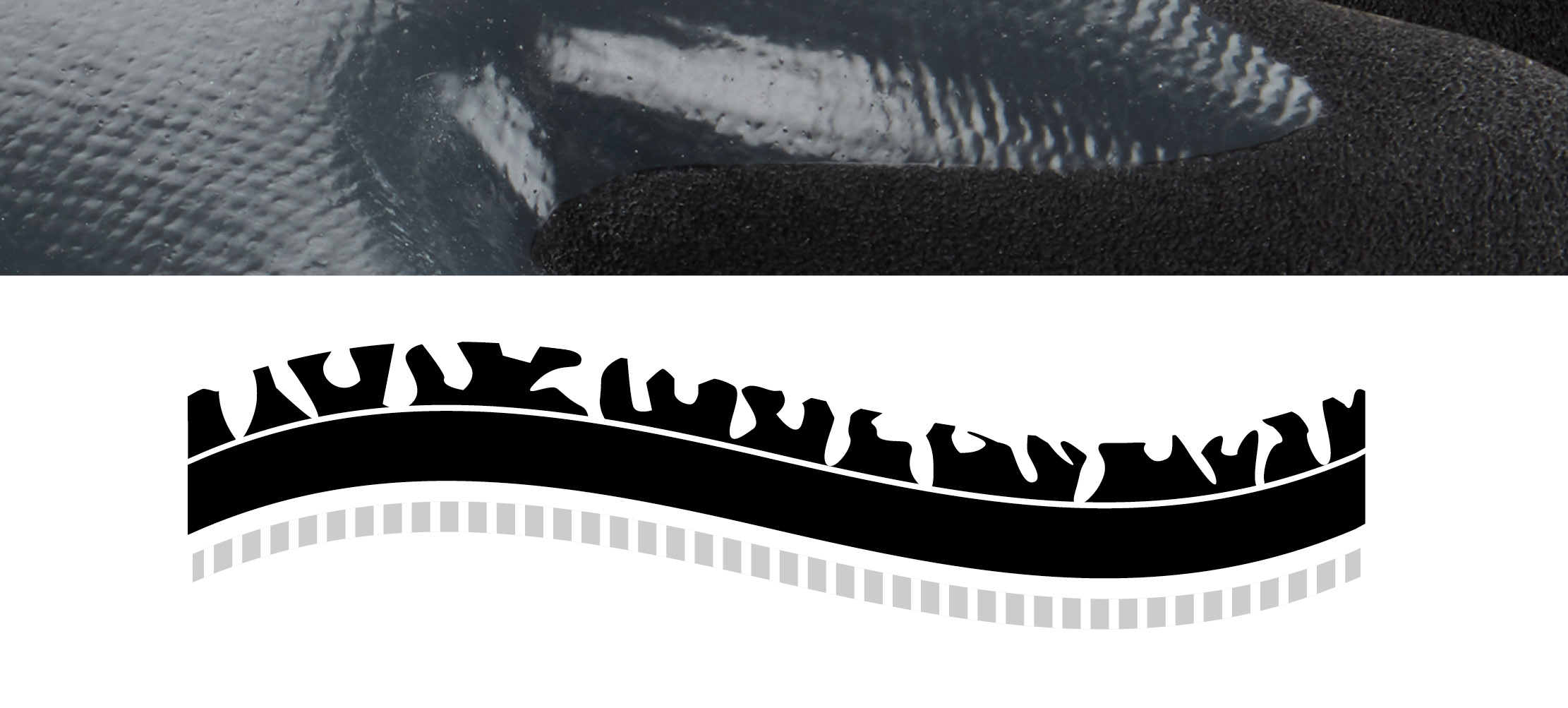

Double-Dipped Nitrile

A double-dipped nitrile coating involves applying two separate layers of nitrile to the glove liner. This process can offer several advantages depending on the specific combination of nitrile types, our 55-6142 Lightweight cut level F full dip nitrile with sandy foam nitrile palm coated glove exemplifies the benefits of a double-dipped nitrile coating, combining a flat nitrile palm with a microfoam palm coating. This construction offers several key advantages across many industries:

- Enhanced Liquid Resistance: The dual layers create a more robust barrier against liquids and certain chemicals

- Increased Durability: The added thickness of the double coating can improve resistance to abrasion, punctures, and tears

- Improved Grip in Specific Conditions: By using different nitrile formulations for each layer, manufacturers can optimise grip for various environments (e.g., a smoother inner layer for flexibility and a textured outer layer for grip)

- Extended Glove Lifespan: The extra layer of protection can contribute to a longer usable life for the glove

Why We Feature Nitrile Coatings in the Tilsatec Range

Our commitment to providing high-performance protection for various industries is reflected in our extensive range featuring nitrile palm coatings. Nitrile coatings provide a robust solution suitable for diverse fields, including construction, manufacturing, automotive, and logistics. The adaptability of nitrile makes it applicable across a wide range of environments. The excellent grip and secure handling provided by nitrile coatings ensures that workers can confidently manage materials and equipment in both dry and wet conditions. This capability not only enhances safety but also improves efficiency within their roles. Additionally, nitrile palm coatings strike a balance between protection, comfort, and dexterity, allowing workers to perform tasks effectively while maintaining high levels of safety.

When Should You Not Use Nitrile Gloves?

While nitrile provides excellent all-around protection, there are specific situations in which it is not the best choice:

- Handling Hot Glass or Metal: Nitrile is not suitable for high-temperature applications. Exposure to extreme heat can cause the material to melt, degrade, or lose its protective properties. In these cases, gloves made from materials such as leather, aramid, or specialist heat-resistant fabrics are recommended.

Nitrile Coatings: Engineered for High-Performance Protection

Nitrile coatings are a key component in delivering high-performance hand protection within the Tilsatec range. When combined with a cut -resistant liner, they offer a powerful combination, providing not only excellent grip, durability, and breathability but also crucial defense against cuts, slashes, and abrasions. This combination ensures that workers in demanding environments have the hand protection they need to stay safe and productive.