Why Understanding Standards Matters

Across industries, puncture hazards pose a significant threat to safety. If wounds penetrate deep enough to break the skin, they risk infection and can cause serious injury. These risks are particularly prevalent in multi-hazard environments such as recycling, construction, glass handling, or metal fabrication. While specialist gloves offer varying levels of puncture resistance, simply looking at a “Level 4” rating can be misleading; a Level 4 under EN388 doesn’t translate directly to a Level 4 under ANSI/ISEA. That’s why understanding the “how” behind the numbers and the specific risks you face is critical for making an informed decision.

EN388:2016 Puncture Testing

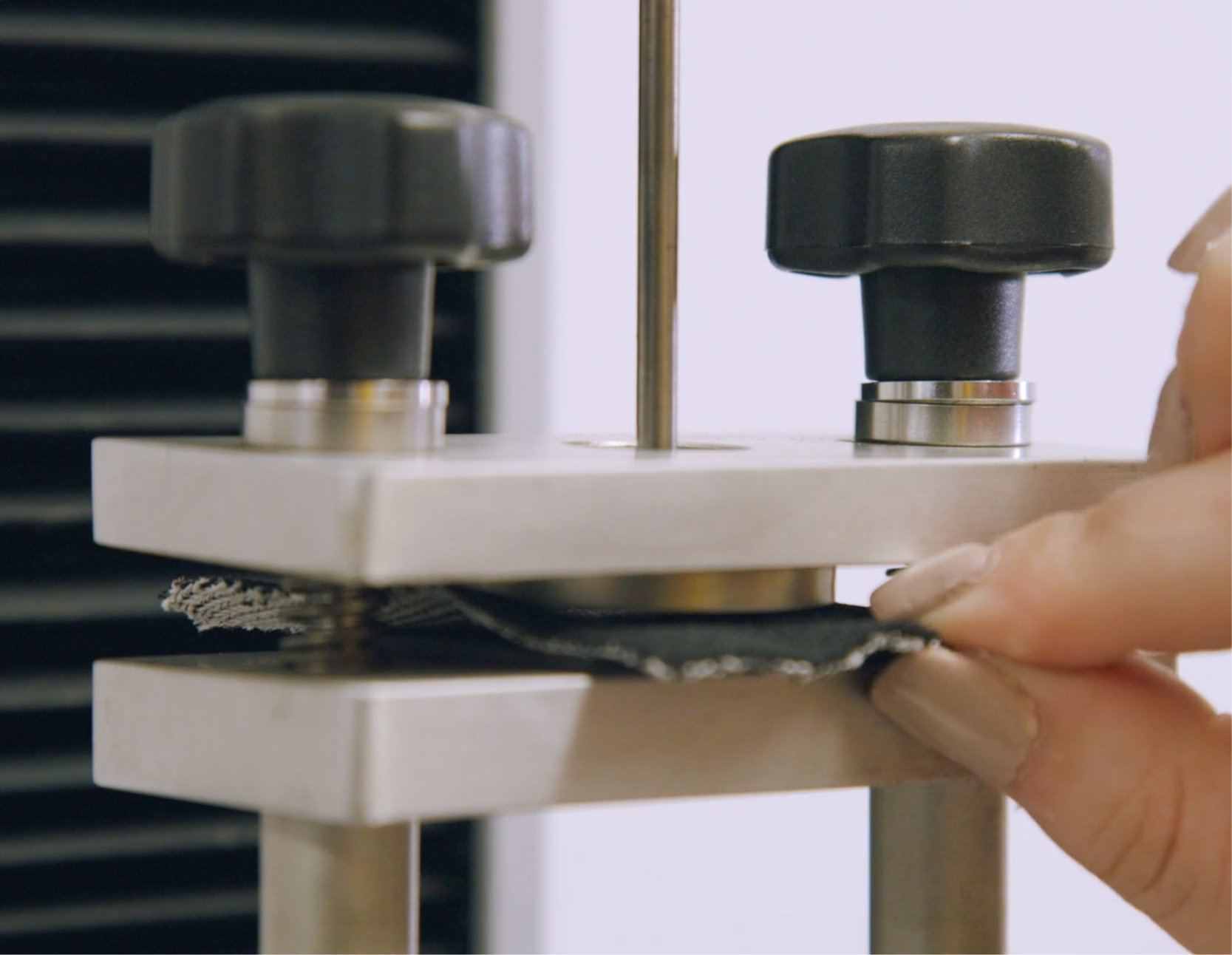

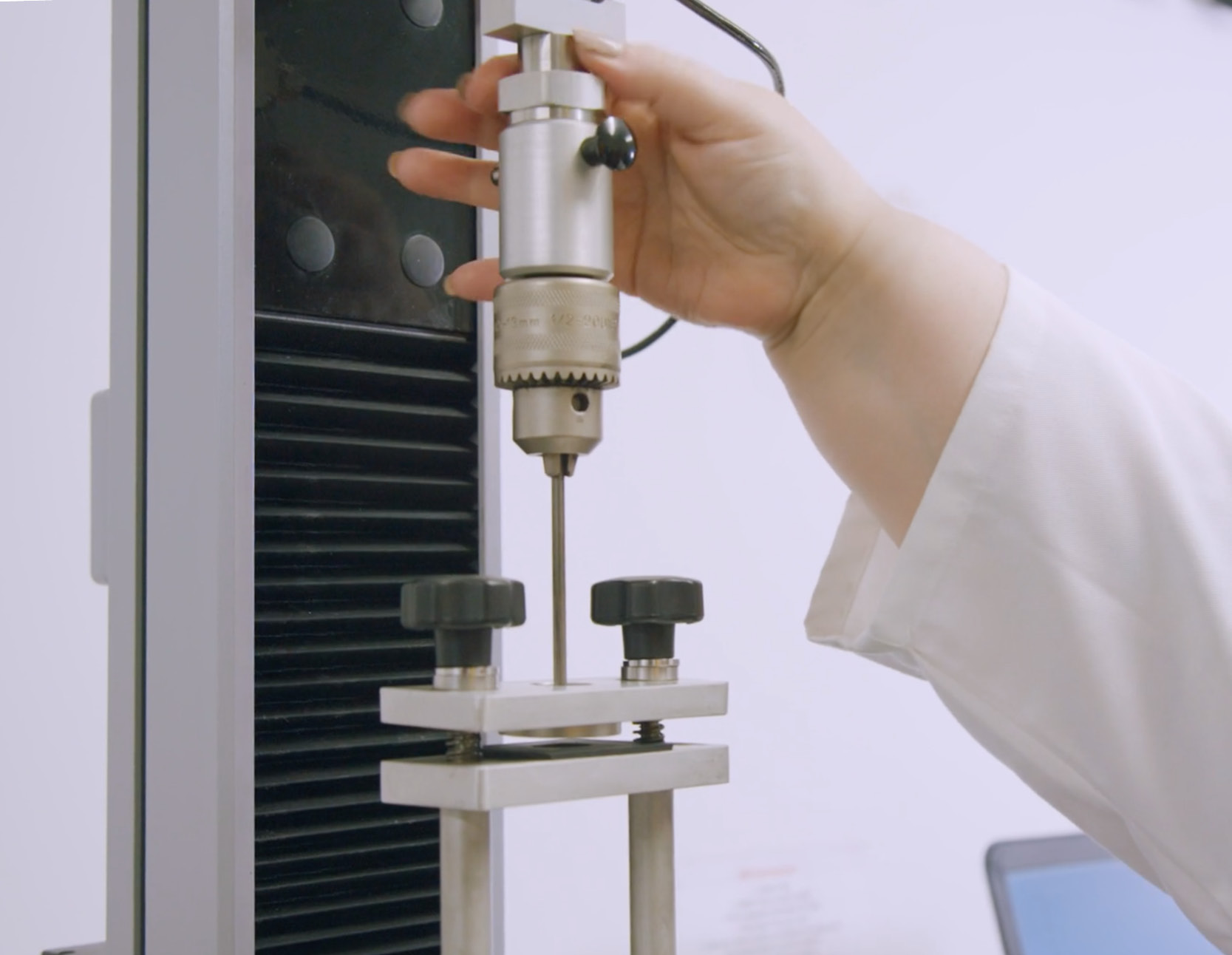

EN388 is the primary glove safety standard in Europe, specifically addressing mechanical risks such as blade cuts, abrasion, tear, puncture, and impact. The puncture resistance test involves a 1mm diameter standard steel stylus driven through the glove material at a constant speed. The force required to puncture the sample is measured in Newtons (N), and gloves are rated on a scale from 1 to 4:

- Level 1: >20N

- Level 2: >60N

- Level 3: >100N

- Level 4: >150N

It’s important to note that this test does not account for hypodermic needles or extremely fine points—it’s designed for typical mechanical hazards such as nails or splinters.

ANSI/ISEA 105-2024 Puncture Testing Overview

ANSI/ISEA 105 is used across North America for the classification of hand and arm protection. The puncture stylus used in this standard has the same specification and dimensions as that of the EN388 test method, yet the rating scale offers a more precise level of detail. ANSI/ISEA 105 ratings range from 0 to 5, depending on the measured puncture force:

- 0, < 10

- 1, ≥ 10

- 2, ≥ 20

- 3, ≥ 60

- 4, ≥ 100

- 5, ≥ 150

This extended scale allows for greater distinction, especially for higher performing gloves.

Does Puncture Resistant Mean Needlestick Resistant?

Both standards test for puncture resistance using a large 4mm wide probe with a rounded 1mm tip, which is fundamentally different from a fine needle. This difference alone accounts for the markedly different puncture ratings that a needlestick puncture test would produce.

ANSI/ISEA 105 and the ASTM F2878 Hypodermic Needle Puncture Resistance Test

ANSI/ISEA 105 covers the classification and test methods for hand protection in industrial applications, and specifically includes a dedicated test for needlestick resistance: ASTM F2878. ANSI/ISEA 105 specifies this method, utilising a 25 gauge needle to measure the force required to penetrate the material. Twelve punctures are performed, and the average force in Newtons is reported. When it comes to needlestick resistance, ANSI/ISEA 105 defines levels 0 – 5 with Level 5 being capable of resisting 10N of pressure.

Needlestick injuries are a potential hazard in various industries, including waste management, recycling, healthcare, and even metal fabrication where fine wire or splinters can mimic needle-like penetration. The ASTM F2878 test method specifically assesses the force needed for a single-use hypodermic needle to penetrate the protective material, offering a vital measure for environments with fine-point hazards.

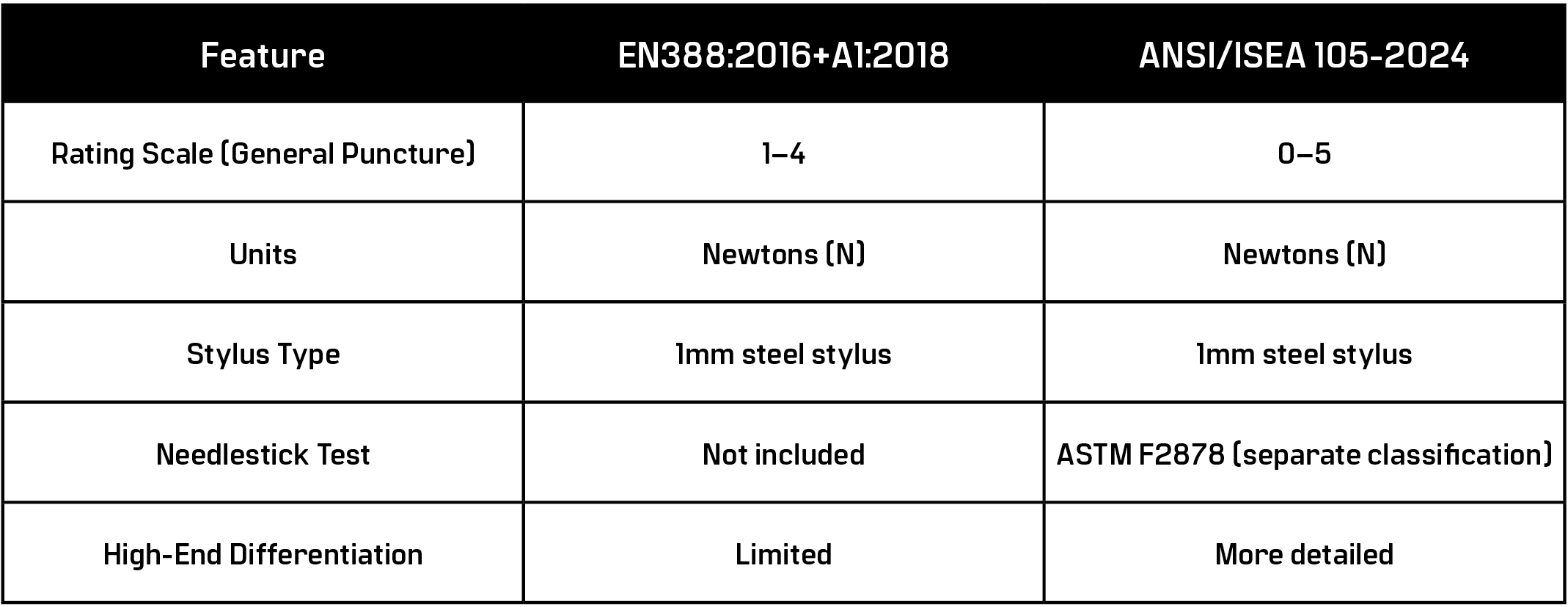

Key Differences between EN388:2016 & ANSI/ISEA 105:2024 Puncture Test

The Real Impact of Puncture Injuries

A puncture wound, even seemingly minor, can have severe consequences far beyond a simple skin penetration. Unlike cuts that often bleed freely and help flush out contaminants, puncture wounds can seal quickly, trapping bacteria, debris, or hazardous substances deep within the tissue. This can lead to serious infections, including bacterial infections like Staphylococcus or Pseudomonas, which may result in cellulitis, abscesses, or even more severe conditions like osteomyelitis (bone infection) if the object reaches bone.

In environments with biological hazards, such as waste management or healthcare, the risk of blood-borne pathogen transmission (e.g., Hepatitis, HIV) from contaminated needles or sharps is a critical concern. Beyond infection, deep punctures can cause damage to nerves, tendons, ligaments, and even blood vessels, leading to long-term pain, loss of sensation, impaired mobility, and in extreme cases, permanent disability or amputation.

The Importance of the Correct Puncture Resistance Level

Given the potential severity of puncture injuries, selecting the appropriate level of puncture-resistant glove is not just a recommendation; it’s a critical safety imperative. An under-protected hand can lead to significant worker injury, lost work time, medical costs, and reduced productivity. Conversely, over-protecting can hinder dexterity, leading to fatigue or even increased risk by making fine motor tasks more challenging.

To ensure optimal protection, a thorough risk assessment of the specific hazards in your workplace is essential. This includes identifying the types of sharp objects workers might encounter (e.g., fine needles, nails, glass shards, metal splinters), the force at which they might impact the hand, and the potential for contamination. By understanding both the type of puncture hazard (general vs. fine point/needlestick) and the required force resistance, you can align the glove’s certified protection level with the actual demands of the job, ensuring your team is equipped with the precise hand protection needed to stay safe and productive.