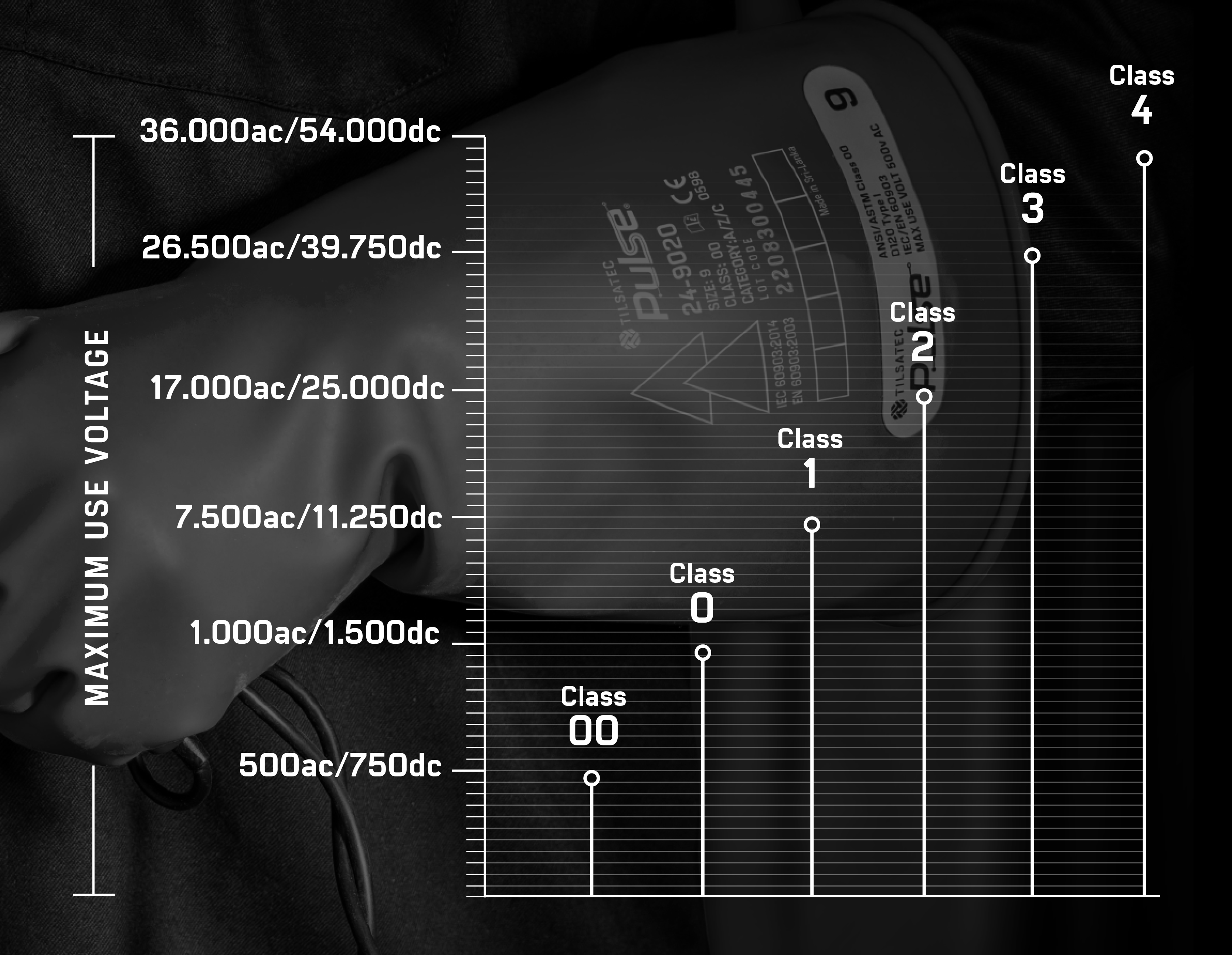

What are Electrical Class Ratings?

The electrical class rating is based on the glove’s ability to protect against electrical hazards. These ratings range from Class 00 to Class 4, with each class indicating the maximum voltage the gloves can withstand. For example, Class 00 gloves are designed for use with voltages up to 500 volts, while Class 4 gloves can handle voltages up to 36,000 volts.

The Importance of Electrical Class Ratings

Understanding the correct electrical class ratings for gloves is essential for the safety of workers in industries that handle electrical wiring, machinery, and control cabinets. Using gloves with the appropriate rating can prevent electric shocks and burns, significantly reducing the risk of severe injury or death. By selecting the right gloves for the task, workers can protect themselves while performing duties such as electrical maintenance, troubleshooting, and repairs.

How to Select the Right Gloves

Choosing the correct gloves begins with assessing the voltage of the electrical equipment you will be working on. Once you know the maximum voltage, you can select gloves with a corresponding class rating. It is important to choose gloves with a rating higher than the voltage you expect to encounter to ensure an adequate safety margin. Additionally, the fit and feel of the glove are important; it should be snug but not too tight, allowing for unrestricted movement.

Insulated Glove Care and Maintenance

The protective capability of insulated gloves can be compromised if they are damaged or not properly maintained. Regularly inspect your gloves for any signs of wear, tear, or punctures. If any damage is discovered, the gloves must be replaced to ensure protection from electrical hazards as the protective capacity can be compromised.

Gloves should be stored in a clean, dry area away from direct sunlight and harsh chemicals to prevent degradation. Proper care and maintenance will extend the life of your gloves and ensure they continue to provide reliable protection.

Insulated Glove Care and Maintenance

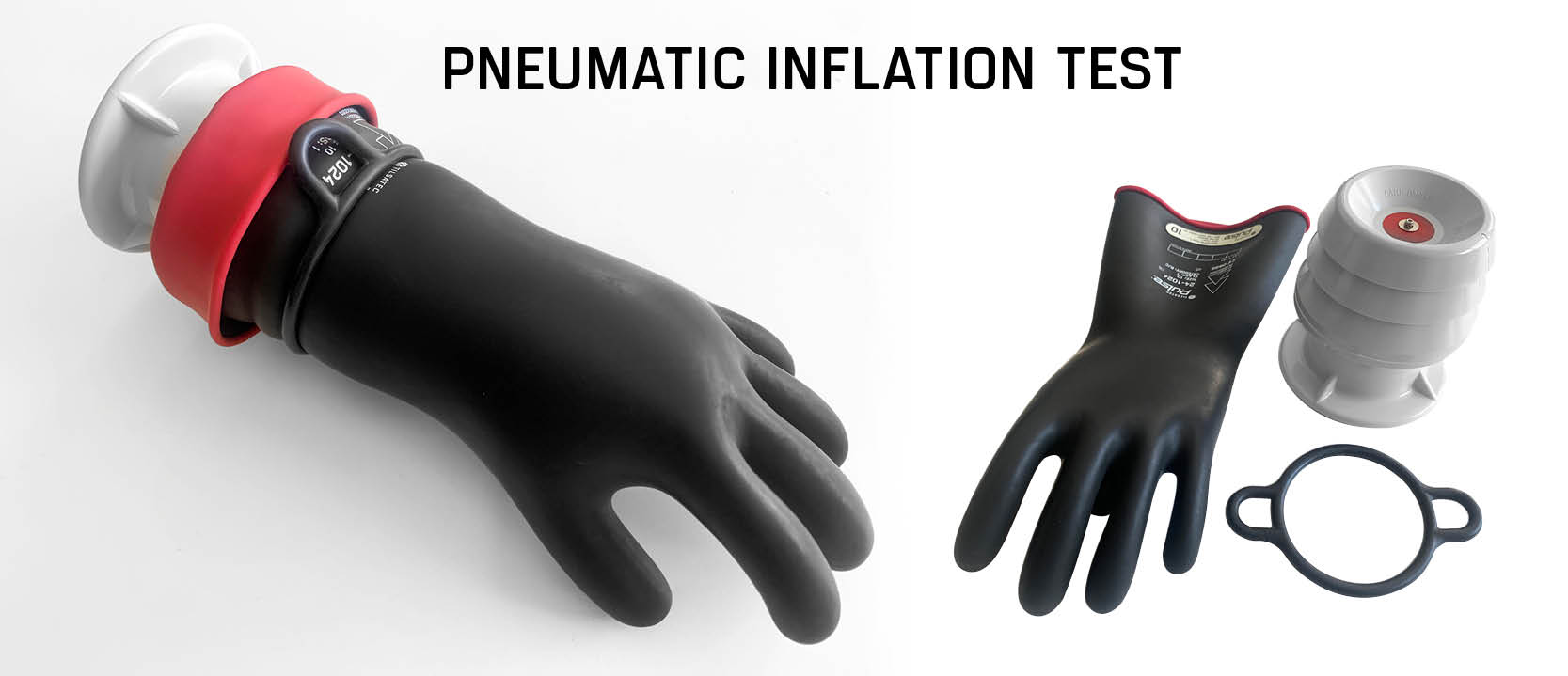

Electrical insulating gloves do not have an expiration date; however, they must undergo routine inspections to ensure they remain functional. For Class 00 and Class 0 gloves, a visual inspection before each use and periodic inflation tests are considered sufficient.

How to Test Your Insulated Gloves

Perform a visual inspection of the gloves before each use. Look for any nicks, tears, or potential pinpricks. Any holes indicate that the gloves will not provide adequate protection and must be replaced.

Electrical gloves are a necessary component of worker safety, protecting against electrical hazards. Understanding the class ratings and selecting the appropriate gloves for your industry and specific role can greatly minimise the risk of accidents and injuries caused by electricity.

For more information on hand protection for electrical safety, explore our Tilsatec Pulse® range of insulating gauntlets, which provides a comprehensive breakdown of the class ratings for our electrical gloves and their typical industry applications.